Deep-sea fishing is a frontier where cutting-edge science meets relentless human ambition. At its core lies the evolution of deep-sea gear—engineered not just to survive, but to thrive under extreme pressure, frigid temperatures, and isolation. This article explores how material innovation, sensor integration, environmental intelligence, and human-machine synergy have transformed deep-sea gear from passive tools into intelligent, adaptive systems that redefine safety, efficiency, and sustainability in modern fisheries.

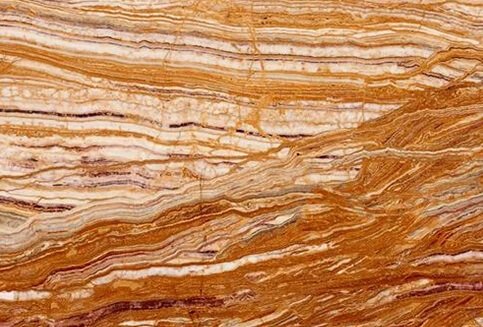

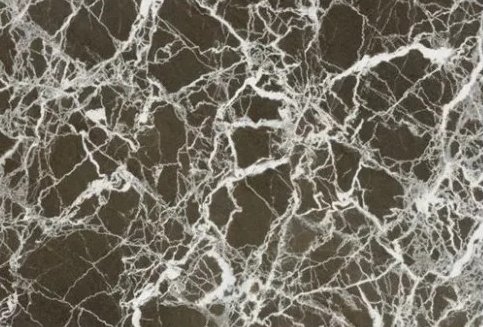

- Steel maintained structural integrity in extreme environments for decades, forming the basis of winches, trawl doors, and anchor systems.

- However, under repeated stress in deep waters—where pressures exceed 1,000 atmospheres—steel exhibits reduced ductility, increasing failure risk.

- Recent advances in composite smart alloys combine metal matrices with embedded nanomaterials, enabling self-healing microstructures and real-time stress redistribution, dramatically enhancing gear lifespan and reliability.

- Embedded sensors measure depth, temperature gradients, and structural stress in real time, feeding data to onboard systems.

- Smart gear detects anomalies such as micro-fractures or excessive strain, triggering alerts before catastrophic failure occurs.

- This shift enhances operational safety and enables preemptive maintenance, reducing downtime and risk for crews.

- Smart systems interpret real-time ocean data to adjust gear tension, deployment depth, and motion dynamics dynamically.

- Machine learning models analyze historical and live environmental patterns to predict equipment stress and recommend adaptive behaviors.

- By minimizing abrupt movements and overexertion, these systems reduce mechanical fatigue and ecological disturbance, aligning operations with sustainability goals.

- AI-assisted feedback systems present critical data in intuitive formats, reducing cognitive load during complex maneuvers.

- Ergonomic interface designs integrate haptic feedback and voice commands, enabling hands-free operation in high-stress scenarios.

- Training programs now emphasize data literacy, preparing crews to interpret and act on real-time insights from smart gear.

- Predictive maintenance algorithms anticipate gear degradation, scheduling repairs before failures occur.

- Autonomous drones and robotic systems may perform localized repairs, minimizing human exposure to hazardous conditions.

- This evolution reinforces the scientific rigor and technological precision driving modern deep-sea fishing practices.

1. The Material Revolution: Steel’s Legacy and the Shift to Smart Alloys

High-strength steel has long been the backbone of deep-sea gear, offering unmatched durability under crushing pressures and near-freezing ocean depths. Yet, traditional alloys face critical limits: susceptibility to cold embrittlement, weight penalties, and inability to adapt to dynamic loads.

2. From Passive Tools to Integrated Sensor Systems

Beyond mere strength, modern deep-sea gear evolves into active participants in operations. Gear functionality now extends from structural support to continuous environmental monitoring and intelligent response.

3. Environmental Intelligence: Gear That Learns and Adapts

Deep-sea environments are unpredictable—currents shift, temperatures fluctuate, and pressure zones vary. Today’s gear leverages environmental intelligence to optimize performance and prevent failure.

4. Human-Machine Synergy: Operator Empowerment via Smart Gear

The integration of intelligent gear transforms the operator’s role—from reactive manual control to informed, strategic oversight.

5. Looking Ahead: The Future of Deep-Sea Gear as a Connected Ecosystem

The trajectory of deep-sea gear is moving toward full integration within marine IoT networks, enabling fleet-wide data sharing and autonomous repair ecosystems.

“The future of deep-sea gear lies not in isolated components, but in interconnected, learning systems that adapt, communicate, and protect both crew and ocean.”

| Key Innovation | Impact on Operations |

|---|---|

| Smart Alloy Integration | Enables self-healing structures and adaptive strength, reducing fatigue-related failures |

| Real-Time Sensor Networks | Provides continuous monitoring of depth, stress, and environmental shifts for proactive responses |

| AI-Driven Decision Support | Empowers crews with actionable insights, lowering cognitive load and enhancing safety |

As deep-sea fishing advances, the science behind gear evolves from steel-bound tools to intelligent, responsive systems. This integration of materials, sensors, and AI not only boosts operational efficiency and safety but also reduces environmental impact—ushering in a new era where human ingenuity and oceanic science align for sustainable discovery.

Explore the full parent article for deeper insights into modern deep-sea techniques